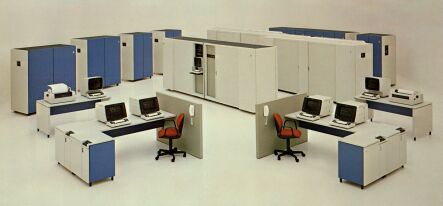

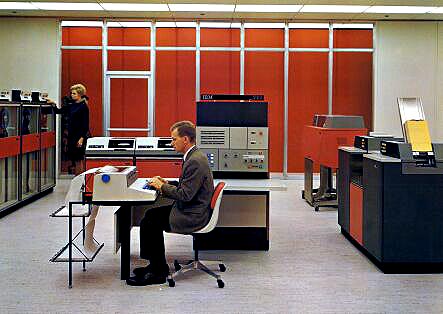

The Model 9000 (center) was in 1990 the largest computer in IBM's new ES/9000 family of processors. This water-cooled six-way multiprocessor provided up to 9 gigabytes (billion characters) of central and expanded storage -- double the processor storage capacity available on the ES/3090 Model 600J, the largest processor in IBM's earlier 3090 families. Commercial performance of the Model 900 was 1.7 to 1.9 times that of the Model 600J. The Model 900 also offered customers up to 256 parallel or Enterprise Systems Connection (ESCON) Architecture fiber-optic vector facilities. With six vector facilities, the Model 900 was two to 2.8 times faster in numerically intensive supercomputing applications than a six-vector ES/3090 Model 600J.

Dynamic Reconfiguration Management. This new function works together with the appropriate level of the MVS/ESA operating system to allow changes to the current system I/O configuration. Channels, control units, and devices can be added or removed without the need for a power on, reset and IPL -- an important contribution to increased system availability.

|

The water-cooled ES/9000 processor models provide these advanced functions: Logical partitioning. The IBM Processor Resource/Systems Manager (PR/SM), a standard function on ES/9000 processors, allows different operating systems to run concurrently in separate logical partitions (LPARs), with a high degree of isolation. In LPAR mode, up to seven logical partitions can be simultaneously active, and up to 14 in physically partitioned configurations. LPAR mode supports System/390 and System/370 architectures. |

Dynamic Reconfiguration Management. This new function works together with the appropriate level of the MVS/ESA operating system to allow changes to the current system I/O configuration. Channels, control units and devices can be added or removed without the need for a power on, reset and IPL -- an important contribution to increased system availability.

|

Integrated Vector Facility The optional Vector Facility provides a specialized execution element to process vectorized programs. Many vectorized application programs are available, encompassing a broad range of engineering and scientific solutions.

|

Integrated Cryptographic Feature. The new optional Cryptographic Feature is designed to strengthen your data processing installation an network security. This facility supports encryption, decryption, message authentication, personal authentication and key management.

Multisystem management. The ES/9000 processor family takes important steps toward key goals, such as "lights-out" operation and increased control of multiple system configurations.

|

Connection options, enhanced with the use of fiber optics, now permit communication links between data centers, as well as between systems within a data center. In addition, a remote data center location can be powered on and off and environmentally monitored using the IBM ESCON Monitor System product.

Within a data center, the ESCON capability allows a systems-complex (sysplex) configuration, enabling workload balancing and backup capability between systems. Multi-system configurations requiring exceptionally accurate time-of-day coordination can now use the IBM Sysplex Timer feature to assure accuracy when timing interconnected systems operations.

|

Environmental changes. The ES/9000 family Models 330 to 900 come with a 50/60 Hertz (Hz) power source and a two-inch water feed between the chiller and the coolant distribution unit. These changes improve power utilization and heat transfer performance of the new models.

The IBM ES/9000 family includes eight water-cooled models: the 330, 340, 500, 580, 620, 720, 820 and 900.

I at the Uni Bonn in 1985: Here I going after the problem. "We" were aware that relaxing the support rods would cause the problem, but I started to worry about the hinge area where the wires were routed into the gate. There is considerable stress/flexture at this hinge.

|

|

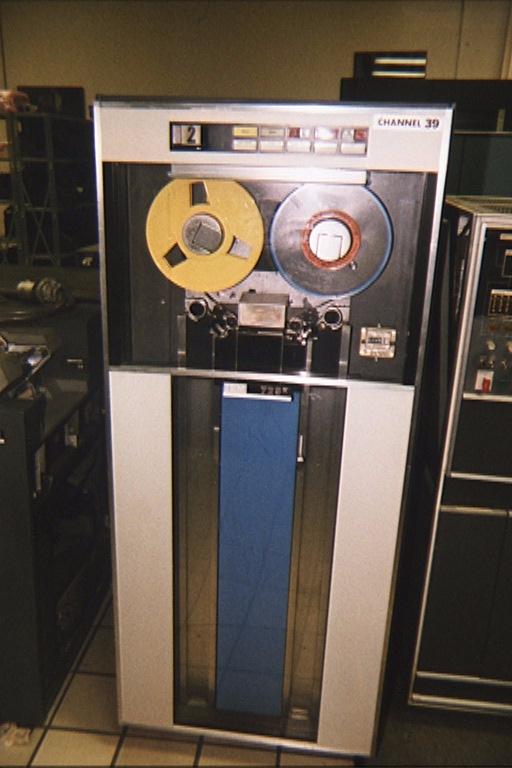

A typical 9-track unit consisted of a tape transport—essentially all the mechanics that moved tape from reel to reel past the read/write and erase heads—and supporting control and data read/write electronics. The transport typically consisted of supply motor, take-up motor, hubs for locking the tape reels in place, a capstan motor (though not necessarily a pinch roller, see below), tape head assembly, miscellaneous rollers which kept the tape in a precise path during operation, and vacuum columns. Problems with wow and flutter, stretched tape, etc could result in corrupted data. The transport had to guide the tape with low tension on the tape without damaging the tape edges, but with enough tension to keep the tape in constant contact with the read/write head.

9-track 800 NRZI and 1600 PE (phase encoding) tapes utilized a .60" inter-record gap (IRG) placed between data records to allow the tape to stop. 6250 GCR tapes used a very tight .3" IRG. 9-track tapes had reflective stickers placed near (10', 14') each end to signal beginning of tape (BOT) and end of tape (EOT) to the hardware. Nine-track tapes commonly had densities of 800, 1600, and 6250 cpi, giving approximately 20MB, 40MB and 140MB respectively on a standard 2400' tape. Signaling EOT (end of tape) with space remaining to write trailer blocks allowed support for multivolume labelled tapes.

|

|

|

Compared to modern disk drives, early hard disk drives were large, sensitive and cumbersome devices, more suited to use in the protected environment of a data center than in an industrial environment, office or home. Disk media was nominally 8-inch or 14-inch platters, which required large equipment rack enclosures. Drives with removable media resembled washing machines in size and often required high-current or a three-phase power supply due to the large motors they used

|

|

|

|

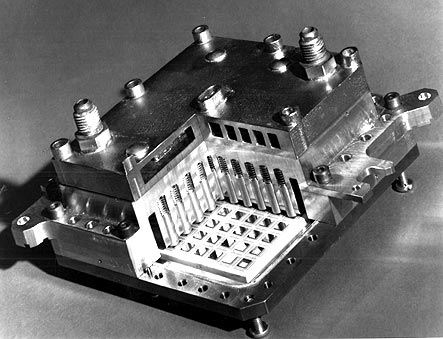

IBM 2311 memory unit, with its six platters.

The IBM 2311 Direct Access Storage Facility was introduced in 1964 for use throughout the System/360 series. It was also available on the IBM 1130 and (using the 2841 Control Unit) the IBM 1800. The 2311 mechanism was largely identical to the 1311, but recording improvements allowed higher data density. The 2311 stored 7.25 megabytes on a single removable IBM 1316 disk pack (the same type used on the IBM 1311) consisting of six platters that rotated as a single unit. Each recording surface had 200 tracks plus 3 optional tracks which could be used as alternatives in case faulty tracks were discovered. Average seek time was 85 ms. Data transfer rate was 156 kB/s.

The 2311 had 10 individual R/W heads mounted on a common actuator which was moved in and out hydraulically and mechanically detented at the desired track before reading or writing occurred. The 2311 was organized into cylinders, tracks, and records. (A cylinder referred to all surfaces the same track on each of the 5 platters.) Record 0 was reserved for timing.

Because the 2311 was to be used with a wide variety of computers within the 360 product line, its electrical interconnection was standardized. This created an opportunity for other manufacturers to sell plug compatible disk drives for use with IBM computers and an entire industry was born.

|