Dr.(Phys.)Dipl.-Ing.Ralf-Udo Hartmann

V8 Motor Reconstruction

How do I rebuild a Mercedes 500 motor ? Answer! I don't.

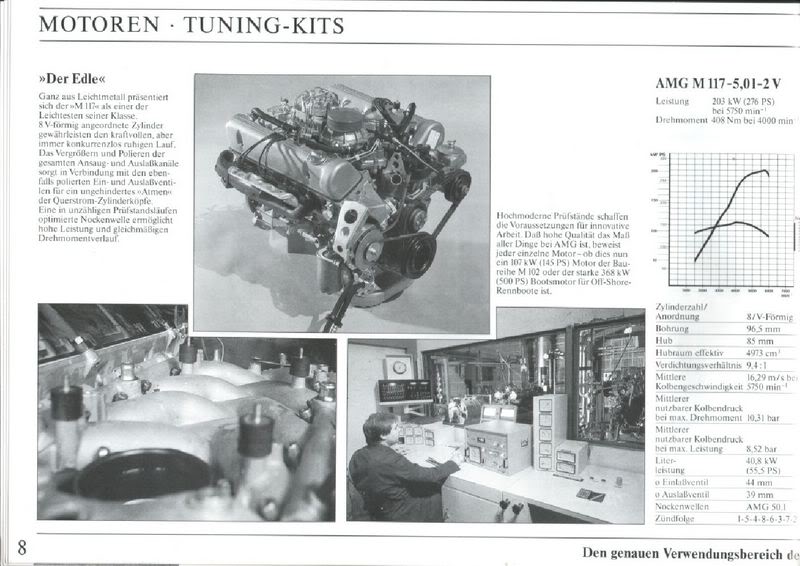

First thing you need to do is go to the bank and draw out a lot of money...get at least $5,000.00 out if you want to do it right. And, when it comes to Mercedes, that's the only way. If you can work it out...get rid of the 500 engine, which is a famous piece of junk, and upgrade to a 560 or even a rebuilt 450 engine. The trans' are all the same for the 380's and 560's. As long as you need a new engine, get one that works. If you're on this site, asking how to rebuild a Mercedes Benz engine, you probably won't be able to do this yourself. You'll need to buy about $1,000.00 worth of special tools, exclusive to MB engines to start with. Then, you'll need a knowledge of over head cam timing. If you mis-align the cam chain sprokets, you'll send a valve right through a pistion. These are very sophisticated engines...they're not like your typical American engines. Basically, buy rebuilding the engine yourself, you'll save about $1,200.00 in labor costs, the rest of the money goes to parts. I suggest you consider spending the extra few dollars and go out and get yourself a long block engine. In the long run, you'll save a lot of time, and probably...money too. I had pretty must lost faith in most garages, but I thought I'd give the garage a try since I've used them many years ago and was very satisfied with the work. And like I said...in the long run, I save money and have a warranty to boot.  Is my crankshaft balanced at 8000 rpm/min?

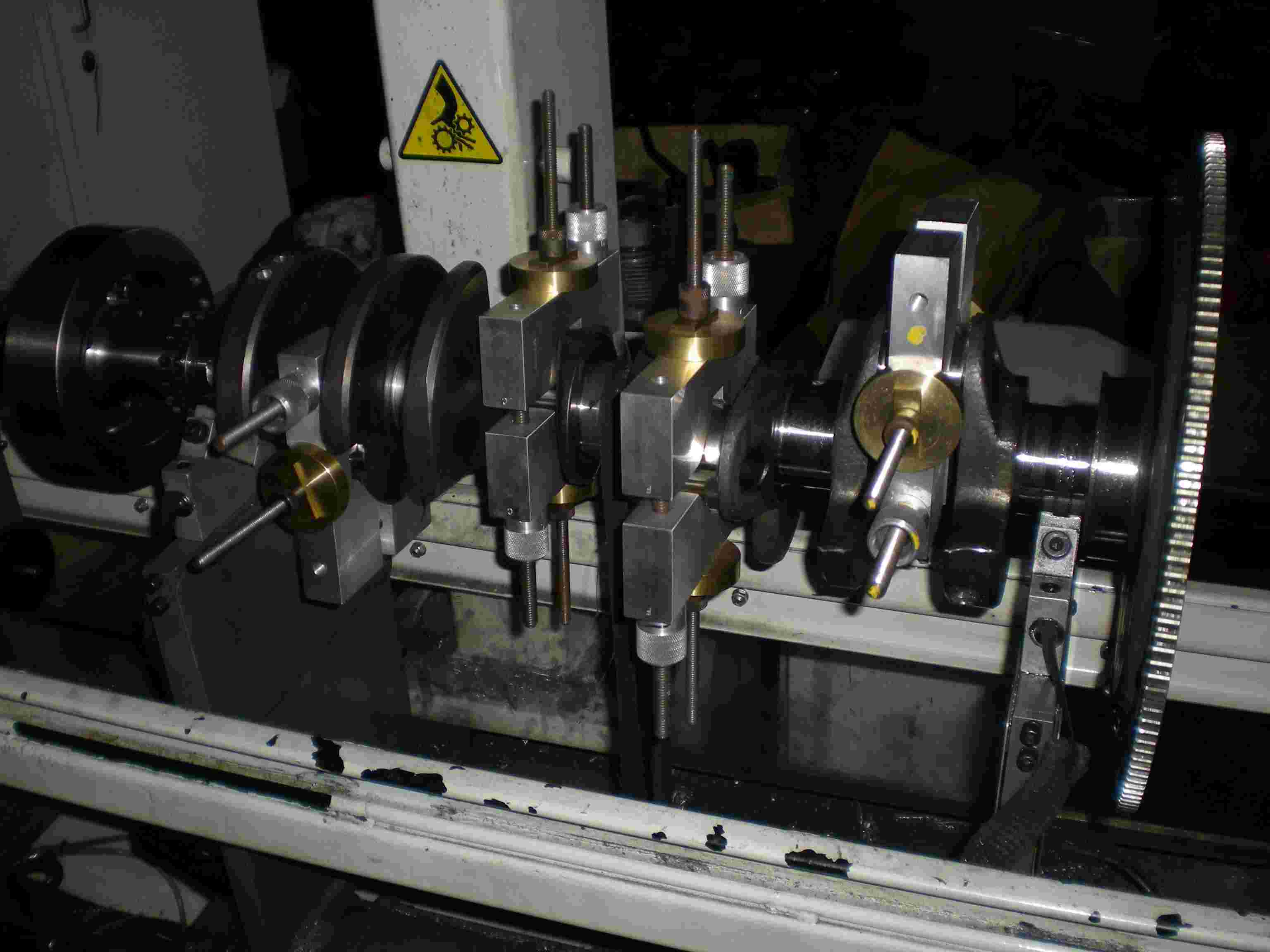

Since different rods and different pistons are different weights, it is impossible to make a crankshaft that is balanced "right out of the box" for any rod and piston combination. All crankshafts must be balanced to your specific rod and piston combination. One thing to remember about engine balance is that anytime you replace parts or assemble parts from various suppliers, it affects balance. No two parts are manufactured exactly the same and there will always be some variation in weight. You have to weigh and balance the individual parts and make sure they work together. Let’s Get Started!

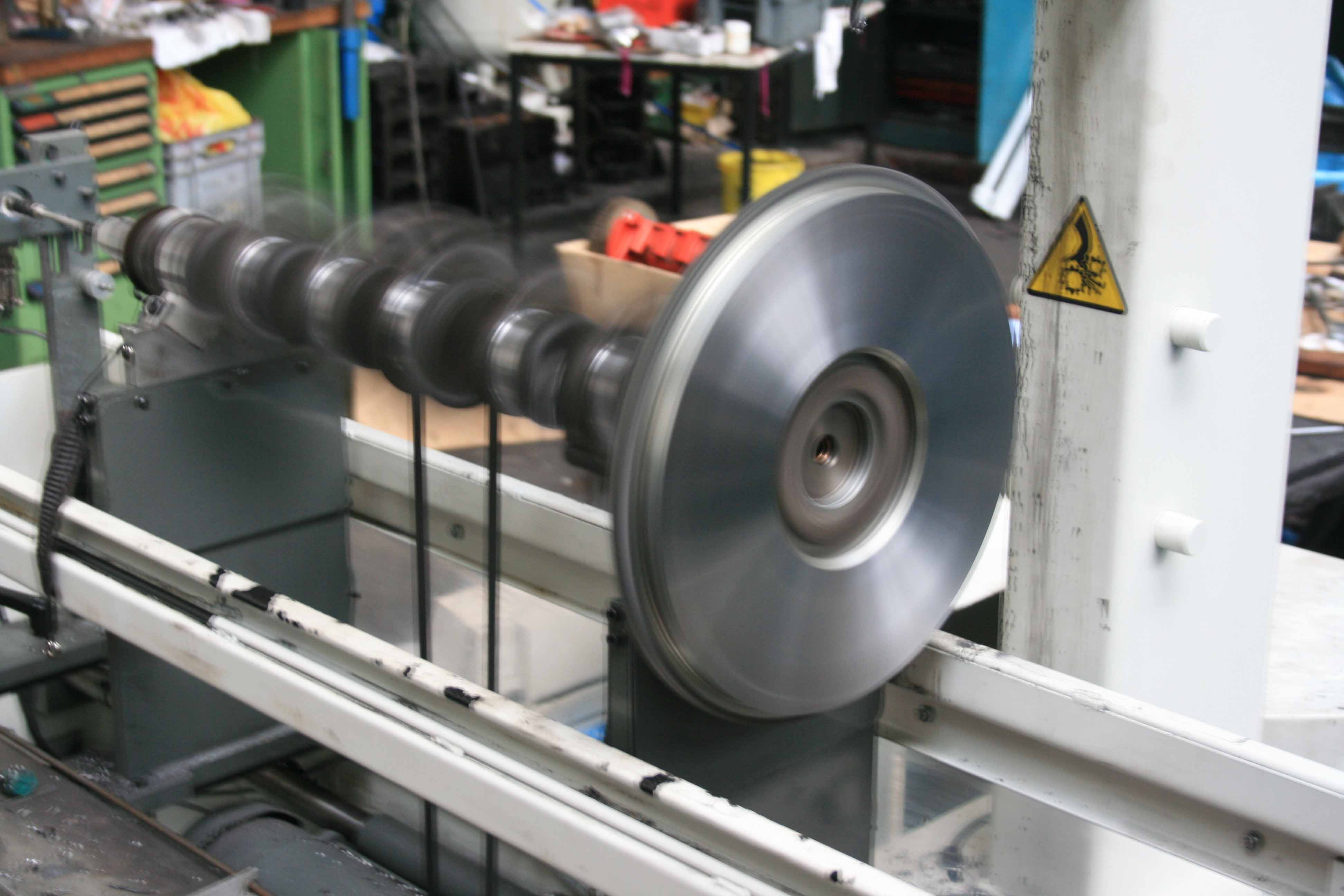

The first thing that we have to do is get the weight of all of the rotating and reciprocating parts. Using the supplied Weight Scale System we start by weighing the Connecting Rods.

The rest of the parts (Pistons, Pins, Rings, Bearing etc.) are logged-in the same way giving the operator a targeted Bob-Weight. The technician will then attach precision weights to the "Moment-Matched” Bob-Weight bodies and mount them on the Crankshaft using the alignment tool.

So does balancing make horsepower? No not in the direct form, it eliminates parasitic forces that would otherwise increase with higher RPM. Elimination of vibrations and possible deformation as a result of the pounding activity is a welcomed benefit. I will probably never take advantage of the full speed, but maybe. I decided to change the speedometer / tachometer Group!

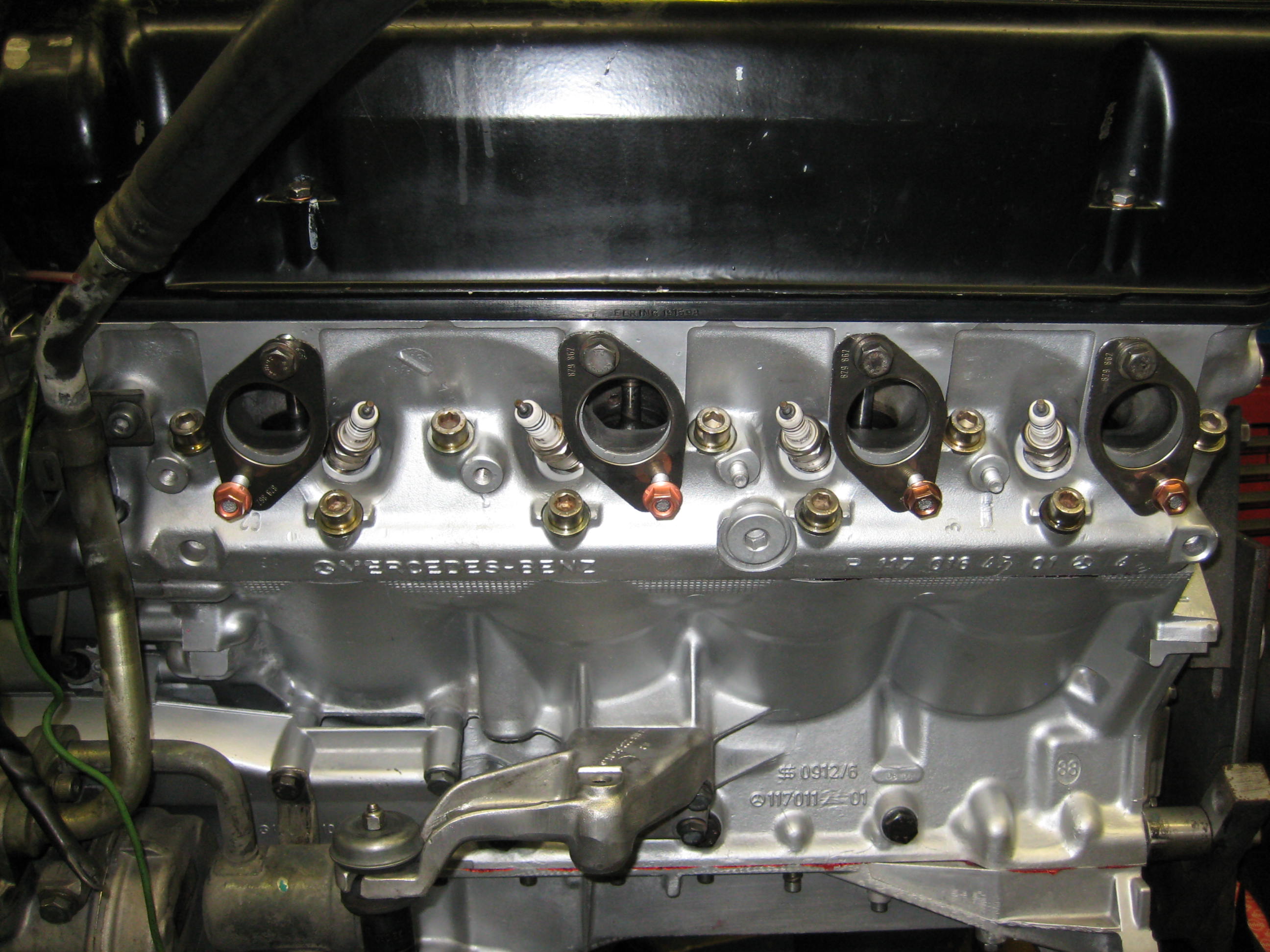

The pistons feature larger ring lands, improved piston dish, skirts, and wristpin mounting while still weighing less than the OEM pistons. Stronger yet lighter Steel Wrist Pins are included with the pistons. The wrist pins are compatible with the OEM rods as well as any aftermarket rod that made to OEM dimensions. High quality piston rings designed for the heavy boost that a built engine will experience are included as well. Each piston have ceramic coating on the piston top for added heat resistance and Teflon coating on the skirts to reduce friction. All the key design features of the Pistons come together to result in an engine that can handle high power levels as well as rev more freely and efficiently thanks to significant weight savings on the rotating assembly.

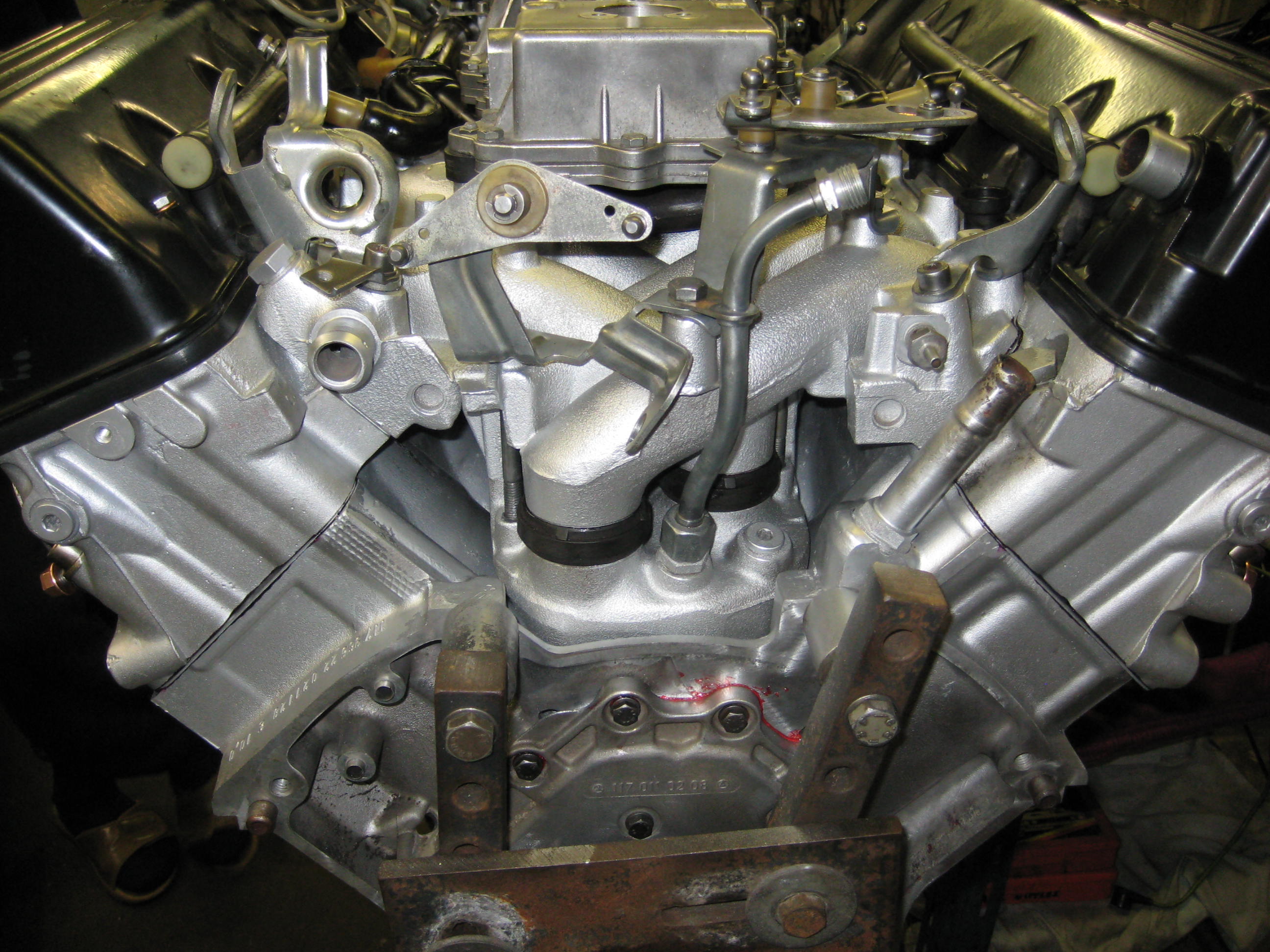

After the 4 month long rebuild, I was pretty happy of looking at the engine.

The stainless steel exhaust system:

The original AMG exhaust system has failed recently after many years of use... and it was time for something new. Finding an original Sebring-made AMG system was difficult, so I went for the next best thing.. which is to get a stain-less steel customs exhaust put in. The sound is nice at WOT and is quiet at highway speeds and above.

Here is my W126 when measuring the old exhaust system.

By chance, I met a young man who builds complete stainless steel exhaust systems from VA4, namely concerns fully and individually customized by request of looks and sound. I'm super excited about my system!

It gives off the vehicle and two days later you get this back completely finished! No circus with assembly, pass inaccuracies, etc. ..

Note: Our time has become so fast-lived, that you can not keep up with all this new information world almost step. Yesterday's date, especially in the automobile sector, yesterday's news may not be tomorrow, because every developer is still "overtop". But there are things on their technical reliability you can count a few years and these include stainless steel exhaust systems or similar high quality materials to happiness. etc.  Kompressor-Supercharger

Kompressor, German for supercharger, is a badge found on Mercedes-Benz marques. The badge is not widely used by other motor manufacturers.

The first supercharged Mercedes was developed in 1921 by a Daimler-Benz team with assistance from Ferdinand Porsche. Mercedes became the first manufacturer to install superchargers on some production models. The designation "K" on Mercedes usually means "Kompact" but can mean "Kompressor".

A supercharger is an air compressor that increases the pressure or density of air supplied to an internal combustion engine. This gives each intake cycle of the engine more oxygen, letting it burn more fuel and do more work, thus increasing power.

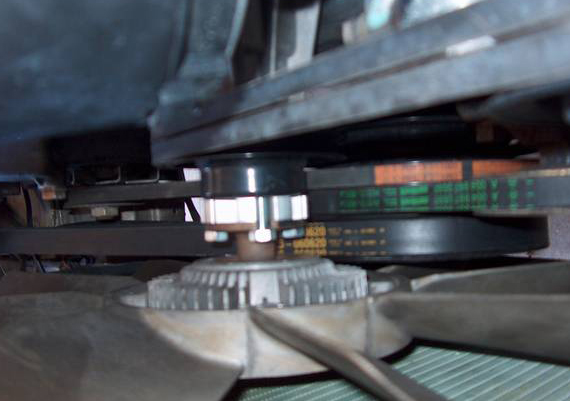

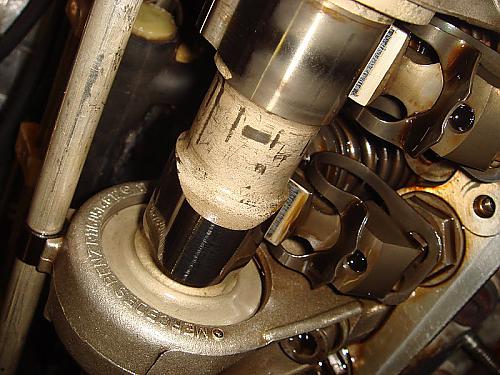

Power for the supercharger can be provided mechanically by means of a belt, gear, shaft, or chain connected to the engine's crankshaft. When power is provided by a turbine powered by exhaust gas, a supercharger is known as a turbo supercharger - typically referred to simply as a turbocharger or just turbo. Common usage restricts the term supercharger to mechanically driven units.

|

Menue

Search

Entries archive

Calendar

Search

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||