But we jump times back in time as I solved the problem with the ECONOMY ad! I have noted all the steps in image and video. Let's start with the left multifunction display

|

|

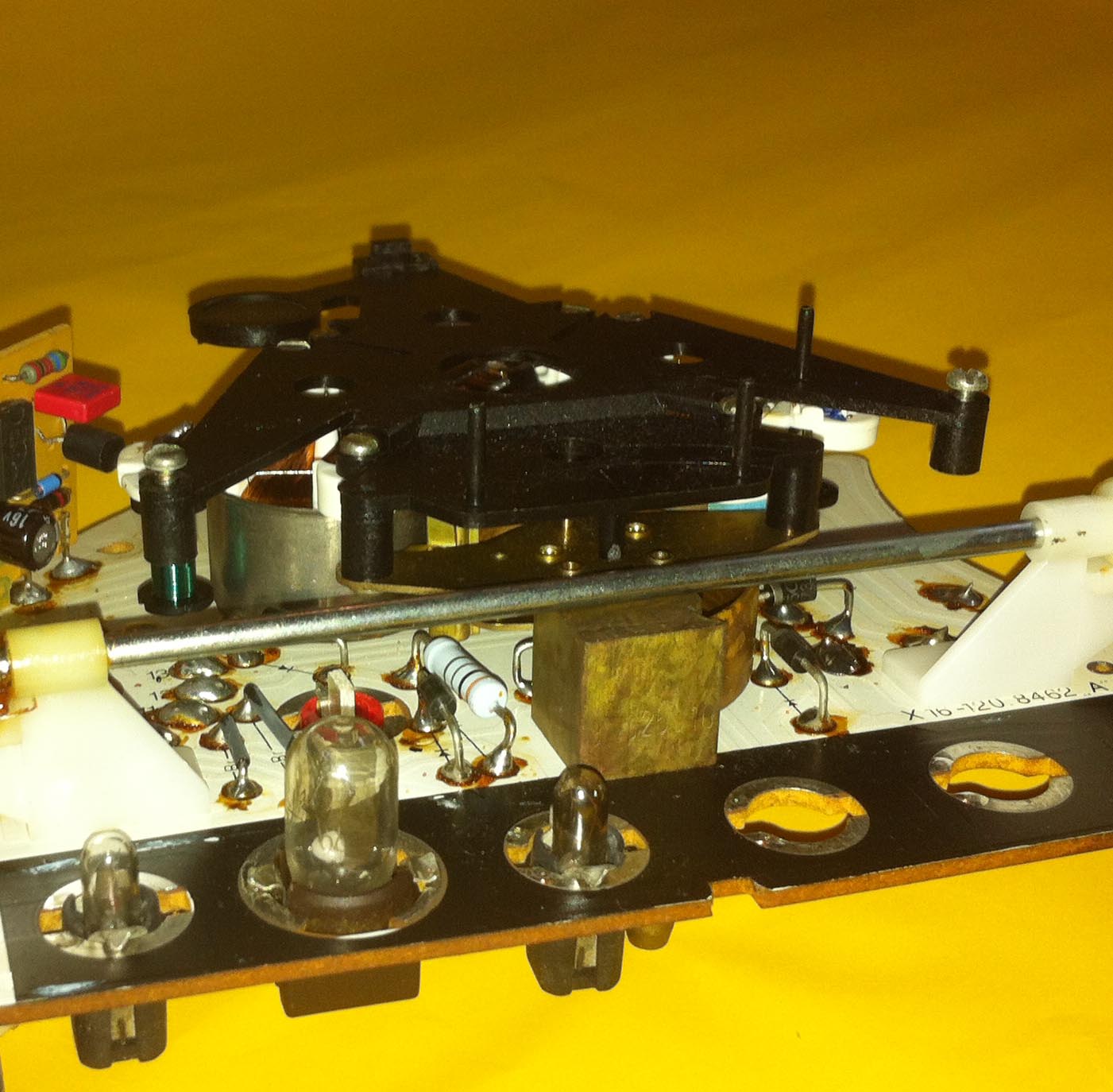

The ECONOMY display should also indicate the pressure of the compressor. The existing vacuum gauge should really also can show a positive pressure. So I have the component (the cube center right) looked at times more accurate.

Once viewed up close looks this purely mechanical component, after a good 30 years of faultless use, like new! A precision mechanical masterpiece.

So now once on the functioning and problems: The state of the engine sucks the air. The more compression the engine has the more negative pressure. If you can roll out the engine in gear, the display goes even higher, because when the throttle is to produce the piston a vacuum in the intake manifold. The throttle valve is in front of and behind the throttle valve prevails constant pressure. Under load and with increasing speed now increased by the mechanically driven compressor, the boost pressure. How exactly is this component behaves with increasing pressure in the intake manifold? This is to show a simple experiment.

In the experiment, I use a syringe to a vacuum build up and then switch to a pressure increase. In the video you can see how the pointer moves to the right when I pull the piston and thus producing a vacuum. If I press the piston into it now, I create a positive pressure and the pointer moves to the left. So the ECONOMY indicator can also show a positive pressure.

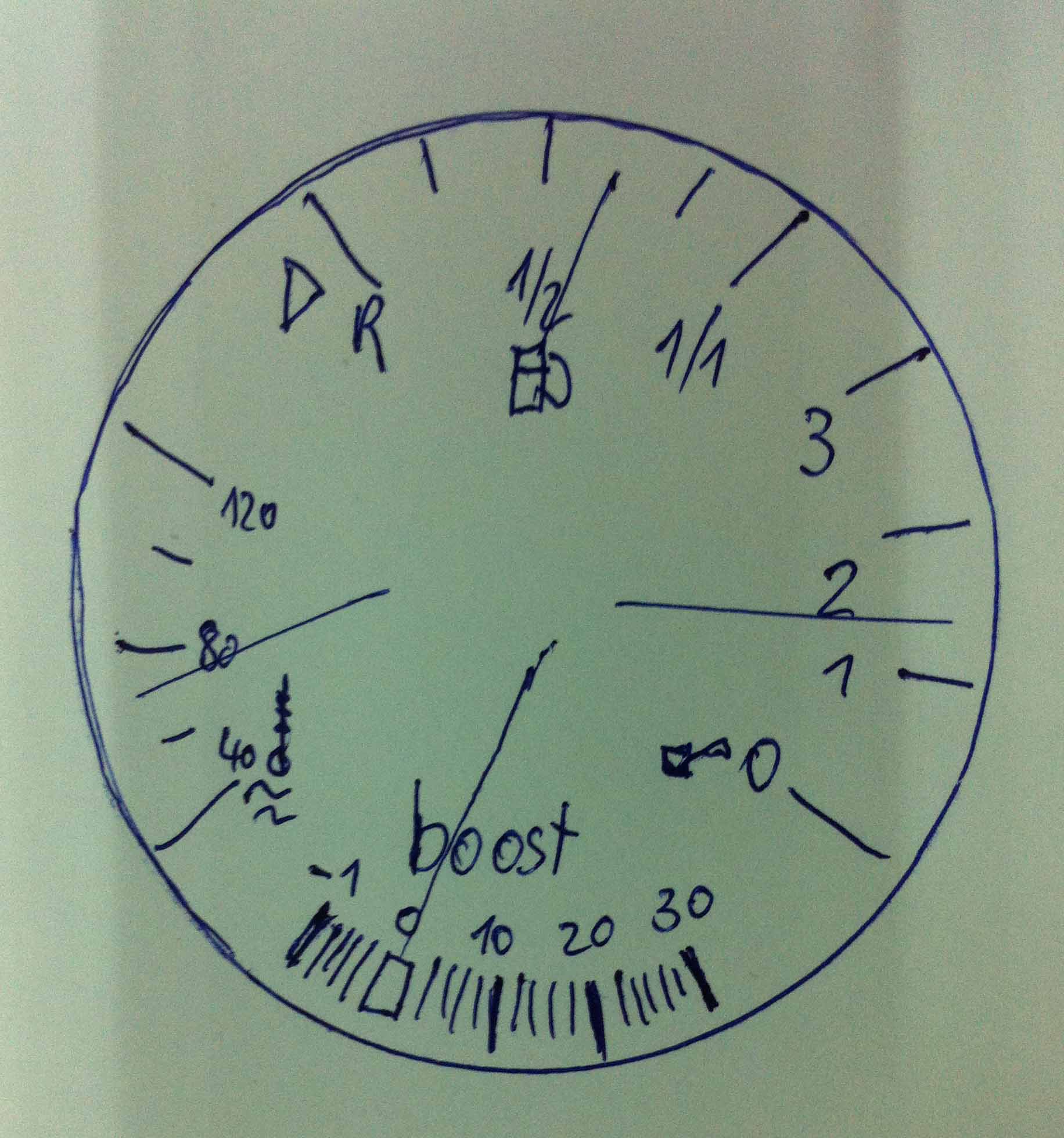

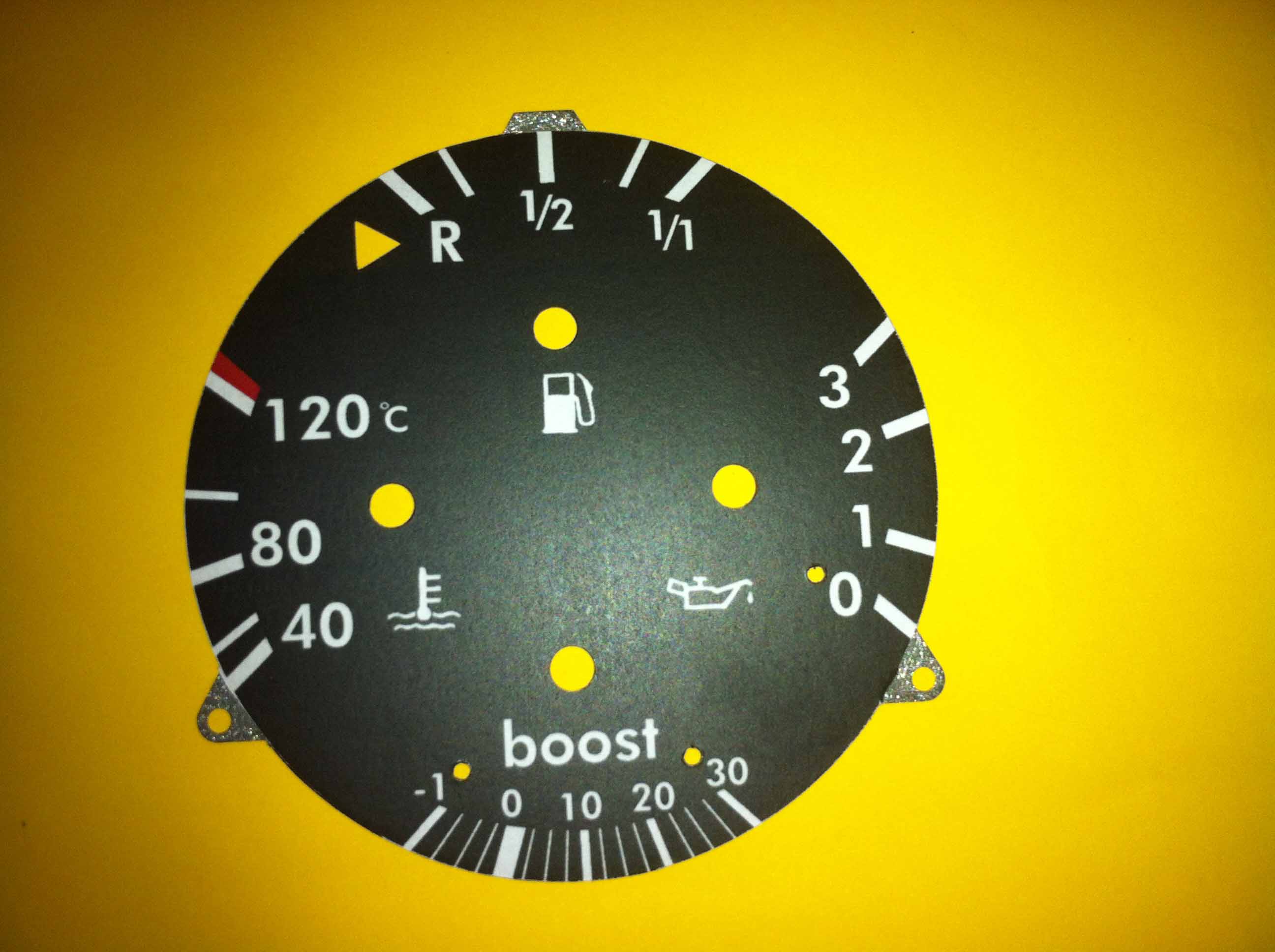

For comparison, the parameters I use a PRO-COMP meter. So I know in which hand position which pressure or vacuum is displayed. The individual hand positions I hold in a list and then create a preliminary sketch for the production of the disc.

|

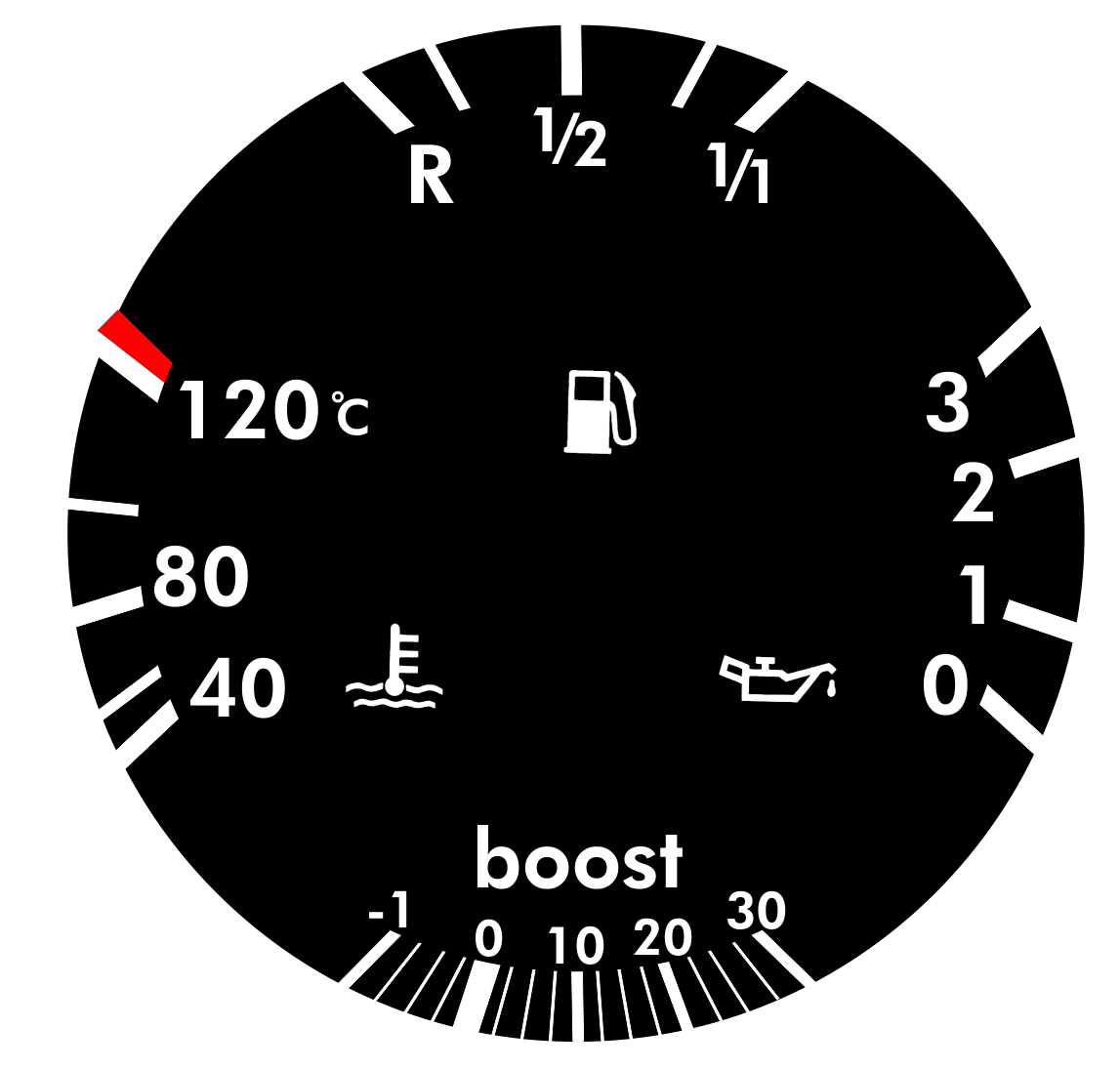

From design to digital template |

|

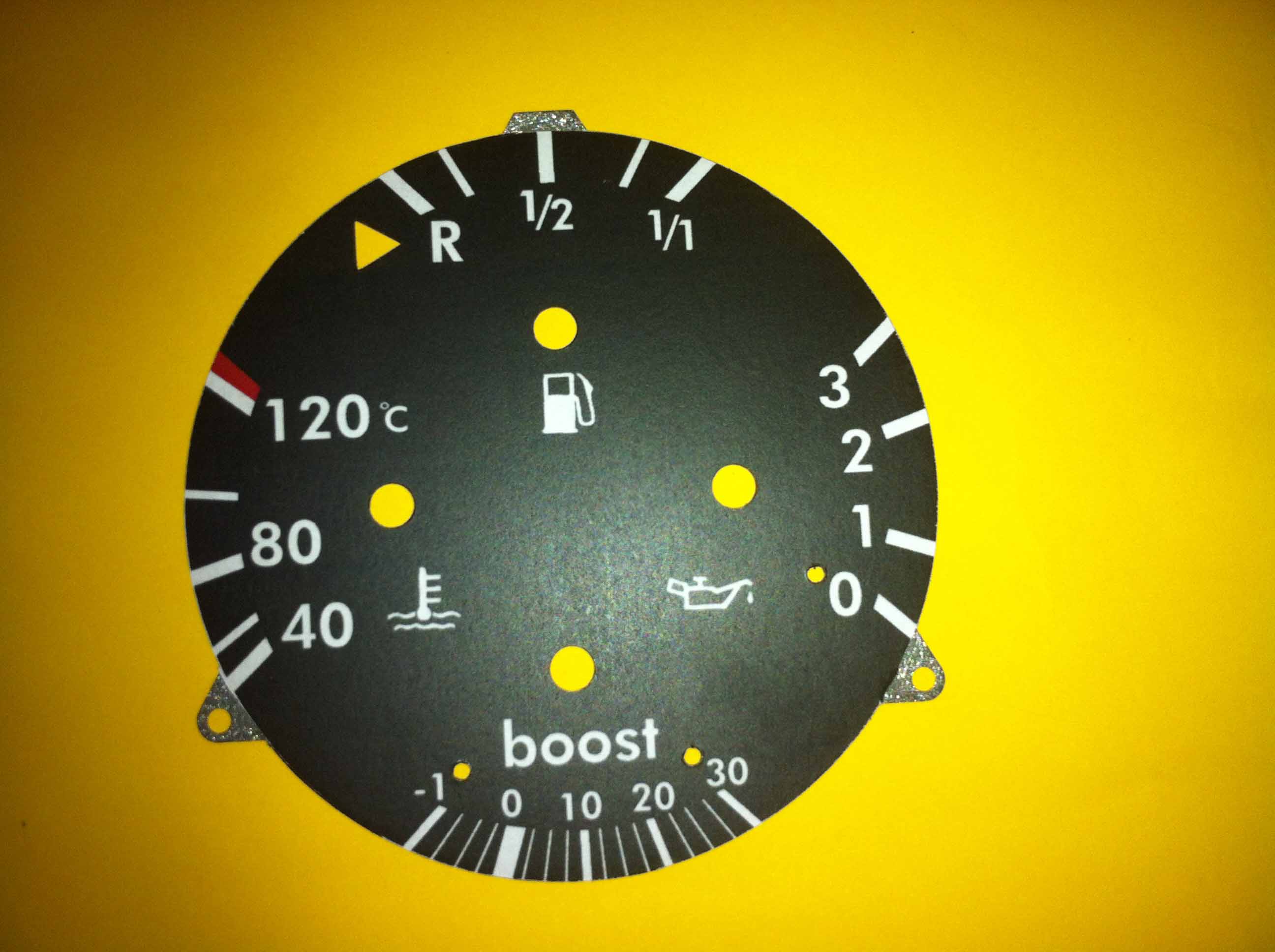

Here you can see Haris Kadic of www.shk-tacho.com in digitizing my freehand sketch. It is based on the design of a speedometer unit, to be seen in the foreground of the same type. For the imagery i would like to thank! Sven and Haris Kadic! |

|

That was the preamble. Now finally can replace with the start of the discs. Here again, for comparison Economy version with the Boost version.

Only the tachometer at 9000 rpm/min Syndicate!

What you need:

A first transformer having primary and secondary 220V 5 -15V (a halogen lamp or bell transformer)

A second rectifier as B80C1500 etc.

A third resistor 10K / 0.5W

The secondary side of the transformer is connected to the AC input of the rectifier. The resistor is soldered between the DC outputs of the rectifier. The (-) output of the rectifier is connected to ground of the tachometer, the (+) output of the rectifier is connected to terminal (TD) of the tachometer. Furthermore, the tachometer via terminal is to supply (+) and ground with 12V DC voltage.

|

What appears and, when necessary. Using the Trimmers must be set: 4-cylinder = 3000 1 / min 6-cylinder = 2000 1 / min 8-cylinder = 1500 1 / min |

|

If a transformer supplied with mains voltage, so is the rpm-meter at a frequency of 100Hz. About the 22K trimmer on the board can now synchronize the rpm-meter (Located almost exactly behind the terminals (+) and (TD).